Vehicle body protection with cavity wax

Did You Know

Vehicle service life can be

improved with right selection of wax

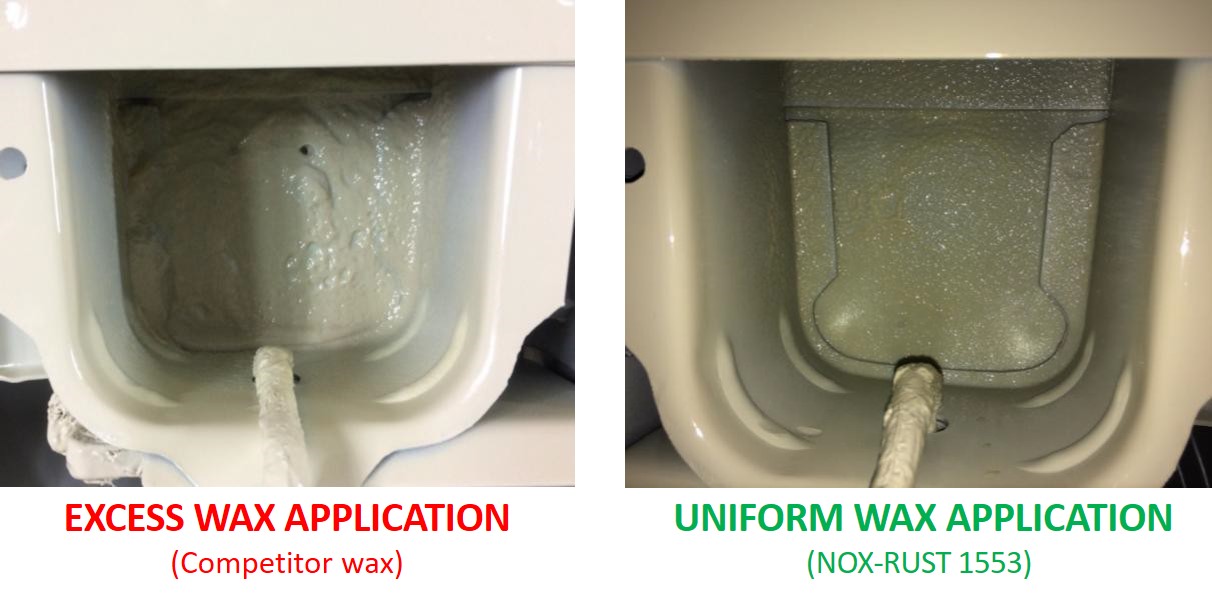

India's second-largest & globally 10th largest manufacturer of trucks was facing issues with the long-term protection of cavities due to high wax consumption and its supply by a local Indian chemical company. The application was long-term rust prevention of the hemming & weld areas of commercial vehicles using cavity wax in the air-less spray system. Our technical team studied the chemical as well as mechanical aspects of the application. Mechanical aspects like spray pressure, nozzle diameter & geometry, and distance were examined. Chemical aspects like thixotropy, viscosity-temperature correlation, film thickness, curing time, and corrosion protection of the existing product were compared with our range of waxes. It was deduced that the high consumption was due to nonuniform layer formation & post-application sagging of the existing wax. It also posed a threat of failure due to rusting during the vehicle's life.

Our corrosion experts suggested NOX-RUST 1553 to the OEM. It is a translucent & semi-firm film coating approved by global OEM manufacturers. Keeping costs in mind, the team ensured no change to their existing setup was needed. Only system parameter adjustments were recommended. Accelerated corrosion tests demonstrated very high corrosion protection of 1000+ Hours SST (Salt Spray Test) at the recommended DFT (Dry Film Thickness). A three-month online comparative study between NOX-RUST 1553 and the existing product was conducted. The rustproof coat using airless spraying was applied in the cavities of the side sill, door, hood, and tailgate of heavy-duty vehicles.

NOX-RUST 1553

translucent & semi-firm film with

1000+ hrs corrosion protection - SST

Uniform layer formation

consumption benefit

up to 20%

The uniformity of layer formation with our product was consistent from day one. Consequently, the average consumption of wax per truck was recorded to be 20% lower as well. Better penetration of wax into crevices was observed while using NOX-RUST 1553 without any dripping and sagging issues.