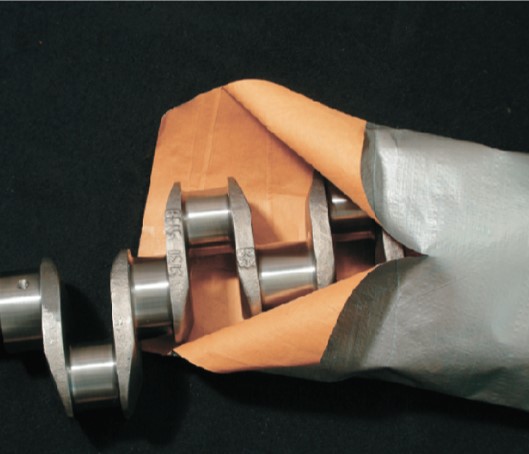

Dry Packaging - Corrosion free parts without Rust Preventive Oil

Did You Know

Corrosion does not occur

in the presence of air alone

For many years, metal components are shipped across continents using a rust preventive oil often in combination with VCI packaging. It is a tried and tested method for export packaging which is considered safe, economical and is a preferred method for export shipments. However, there has been a spike in the demand for corrosion-free parts in dry packaging i.e. without Rust Preventive Oil, to reduce further complications at the receiving location as explained below.

In dry packaging, selection of

right cleaner is very important

VCI should have quality carrier with

better moisture barrier

Conventional Process (Corrosion Prevention with Rust Preventive Oil):

(Manufacturing Location) - Job fabrication>>Cleaning>>Rust Protecting>>Export Packaging

(Receiving Location) - Degreasing or Clean>>Rust Protecting>>Further Protection

Steps will be eliminated in Dry Packaging:

(Manufacturing Location) - Job Cutting>>Cleaning>>Rust Protecting>>Export Packaging

(Receiving Location) - Degreasing or Clean>>Rust Protecting>>Further Protection

Corrosion does not occur in the presence of air alone, but due to a certain amount of water vapour that is always present in the air. By application of suitable VCI technologies, a barrier is provided on the metal surface protecting the parts from corrosion. However, in dry packaging, there are several challenges that are needed to be overcome with the elimination of Rust Preventive Oils. Rust protection is solely dependent on VCI and for VCI to perform optimally part preparation and cleanliness is critical. Therefore, maintaining a high level of discipline in part cleaning, surface preparation and handling of components is crucial to the success of dry packaging.

Steps to be focused & requirement for Dry Packaging:

Export Packing

- Effective VCI Formulation

- Quality carrier with better moisture barrier

Cleaning

- No residues on the surface (low Millipore)

- Use of cleaner with low residual value & better corrosion protection

Daubert Dry Packaging Process:

(Manufacturing Location) - Job Cutting>>Cleaning>>Rust protecting>>Export Packaging>>Export >>Direct Production

The usage of suitable Zavenir Daubert X-CLEAN cleaning fluids and Daubert VCI’s products combined with expert chemical process study can help achieve Dry Packaging with the elimination of redundant steps in the process.

- At the manufacturing location - Application of rust preventive oil application.

- At the receiving location - Washing process and rust preventive solution application.

- The parts fed into the production lines are clean compared to earlier methods.

Given the ever-increasing environmental concerns, OEM’s demand for clean parts without any rust preventive oil are expected to increase in times to come.

Recommended Additional Reads