July 2022

July 2022Volatile Corrosion Inhibitor : VCI Technology, Uses and Benefits

The problem of corrosion starts way backwith invention of metals. In early days we did not see any proper methodology for the prevention of corrosion. Hence, metal-based components and commodities used to have a very short life. With advancements came in corrosion inhibition technologies that included oiling, waxing, and coating metal surfaces with relevant corrosion inhibitors. But now, another kind of packaging is available in the market that does not require any physical coating. That packaging is called VCI packaging which eliminates corrosion during storage and shipping.

What is a Volatile Corrosion Inhibitor?

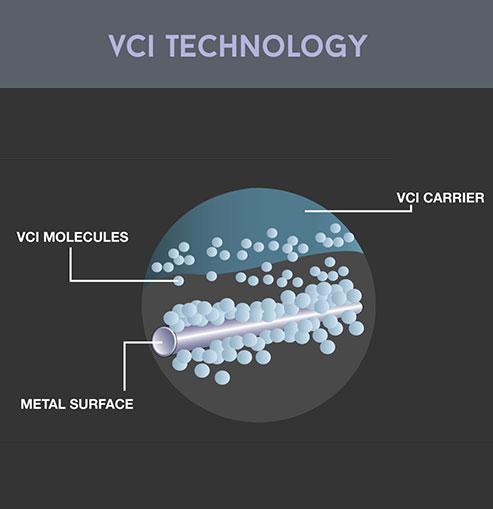

Materials and equipment in nearly all industries require strong protection against corrosion to prolong life. One of the chemicals specialized for this purpose to ensure the longevity of the materials is the Volatile Corrosion Inhibitor. This chemical substance is coated onto the target surface to be protected. It is in the form of packaging paper in which chemicals are volatilized so that the molecules are released onto the surface in an enclosed space to create a strong impenetrable barrier.

Materials wrapped securely in this type of corrosion inhibitor paper are protected for a short duration enough to transport to a different location for deployment or towards the next manufacturing process. The barrier formed protects the surface from moisture, humidity and other external factors.

The name Volatile Corrosion Inhibitor can be interchangeably used with Vapor Corrosion Inhibitor.

Uses of Volatile Corrosion Inhibitor

Since VCI has been invented, it has been a life saver in every industry that makes use of metals or other materials that are prone to corrosion. The products that are prone to rust lose their strength over time and decay in the situation of constant exposure to external elements. To ensure that the metal products and commodities have a long stable lifespan and are retained for years, several corrosion inhibitors are being looked for. VCI packaging is a solution best for packaging items for storage and transportation. Those industries that utilize the VCI packaging materials are:

1. Automotive:

In this industry, the vehicles are all metal-based and need to be secured to ensure long life and extended reliability. This is because cars and other vehicles are used outdoor and always exposed to external elements, like atmospheric air, moisture, sea, and land making them prone to rusting. VCI packaging materials like VCI films and papers form a corrosion inhibiting barrier on the surface of metal. The parts often stored and transported also require protection from corrosion. These include gears, crankshafts, etc.

2. Aerospace and Military:

In this industry, it is very important to keep the weapons and vehicles all safe from corrosion as they are commonly used in wars and for national security. Any amount of degradation is intolerable as only the best quality equipment and long-lasting materials can be truly relied on to protect our country. Hence, VCI packaging materials are employed to form a protective layer on all vehicles, equipment, and weapons.

3. Energy (Oil and Gas/Renewable):

Any commodity that can help store, transport, and retain the energy materials like oil, gas, or renewable forms, needs a potent corrosion inhibitor covering the equipment being utilized. Here, VCI works best.

4. Export Shipment:

When metallic materials or commodities are transported or exported, they need to be protected so that they reach the destination in the optimum condition. That is where VCI packaging is the best solution for safe transportation of any kind of metal-based shipment. It is also best for the storage of materials before the transportation process.

5. Heavy Equipment:

The industry that manufacturers heavy equipment for use in various other industries need to ensure that those machines and equipment are all long-standing and reliable to work with. Here, appropriate VCI packaging materials can be deployed.

Read More: VCI: The Anti Corrosive Packaging

Benefits of Volatile Corrosion Inhibitor

Ease of Application: VCIs are available in various forms, making them easy to apply to metal surfaces.

Non-Destructive: They create a protective layer without altering the metal's appearance or properties.

Long-lasting Protection: VCIs provide continuous corrosion protection for extended periods, even in challenging environments.

Multi-Metal Compatibility: Suitable for protecting a wide range of metals and alloys.

Cost-effective: Require minimal application and maintenance, reducing overall corrosion management expenses.

Environmentally Friendly: Non-toxic and do not contain harmful chemicals or heavy metals.

Ease of Removal: Can be easily removed from metal surfaces using common cleaning methods.

Zavenir Daubert: The VCI Hub

Zavenir Daubert has been working on developing corrosion inhibition technologies for a long time now. Daubert has been able to invent VCI technology that can be one of the best and simplest corrosion inhibition solutions. Those VCI technologies developed include Daubert VCI Multilayer Technology, Daubert VCI technology, and Daubert VCI Desiccant Technology. All these have different applications due to various different products belonging to each category.

Some of the top Zavenir Daubert products are:

- Daubert VCI Paper

- Daubert VCI Films

- Daubrite NF VCI Emitter CUM

- Daubert MPI Foam

- Daubrite 5 VCI Emitters

All these VCI packaging materials and products have different applications and can be utilized based on the technologies above. With the diligently working professionals behind Zavenir Daubert’s success, the customer satisfaction rate is expected to climb exponentially in the years to come making it one of the top global corrosion inhibition solutions providers.

Frequently Asked Questions

1. What are the components of Volatile Corrosion Inhibitor?

Volatile Corrosion Inhibitors consist of typical salts of moderately strong bases and weaker volatile acids. The bases include amines while the acids are the combinations of nitrous, carbonic, and carboxylic.

2. What are the examples of a volatile corrosion inhibitor?

Some of the most common volatile corrosion inhibitors used in homes are camphor, nectarine, and paradichlorobenzene used as mothproofing agents.

3. What is VCI paper used for?

VCI paper is a clean and dry paper used for packaging materials made from ferrous and non-ferrous substances. These are used for corrosion prevention by creating a barrier.

4. How do Volatile Corrosion Inhibitors work?

When wrapped in this paper, inhibitor molecules are activated and transferred to the target surface by filling up the vapor space under the packaging. This barrier is strong enough to withstand the external agents for a certain duration.

By Mudit Mathur

(Senior Manager, Product Management & Marketing)