August 2022

August 2022VCI Film Bags and Packaging Sheets

Many industries require storage of their materials in warehouses for the use and/or transport the same to different cities or countries. In this process, there is a possibility of corrosion formation on the metal-based materials exposed to air and moisture. To prevent corrosion, there are VCI based packaging film- bags and sheets are available.

VCI Films and Applications

VCI Film Bags are poly packaging materials combined with VCI chemicals that can be used to pack metal materials to prevent from corrosion during storage and transportation. VCI chemicals emitted from the bags form an invisible layer of 3~5 molecules on the metal surface are able to inhibit corrosion.

These VCI Films also called Vapor Corrosion Inhibitor Packaging Films are available in various sizes, and thicknesses to fulfill the customer needs. These VCI Films are used in various scenarios.

Container Shipment: When transportation of shipment is carried out, there is a need to secure metal-based materials like parts of machinery and other metal components. Due to lot of moisture surrounding the shipment, a good quality VCI film packaging would be the best solution.

Electronic parts: Materials like wires, metal nuts, and bolts need a secure covering of VCI film to ensure rust prevention.

Land, sea and air transportation: Materials being shipped via roads, ships or even via air need rust prevention to ensure that the materials reach the destination intact.

Automobile parts: Automobile parts like crankshaft, gears, engine parts, metal rods, and so on are often required to be stored, and transported to vehicle assembly units across the globe. To keep them in perfect condition of working and assembling for a long time, a good quality VCI packaging film is required.

Read Also: High Flash Rust Preventive Oil

Zavenir Daubert’s Technology in VCI Films

Zavenir Daubert is a service and solution provider working in the field of corrosion prevention for many years. Having prepared the products for use as VCI Films, the team has been diligent in inventing the relevant technology behind it to make it the best solution for rust inhibition.

The highlighting technology behind the product of VCI films is the Daubert VCI Multilayer Technology. At times, single layer VCI film is not enough to protect the metal parts from corrosion. Therefore, a need for multilayer VCI film protection was acknowledged for higher strength and low MVTR. For high performance of corrosion protection these VCI films are combined with Daubert’s proprietary VCI chemicals.

In the VCI multilayer technology, the outer layer of Daubert’s VCI Film prevents any errant molecule of air and moisture from reaching the metal surface for corrosion prevention. Following this, the middle layer is providing physical strength to the VCI film, and the inner layer contains VCI chemical to protect the metal surface from corrosion. Zavenir Daubert has utilized this technology to develop very useful products in the form of Daubert VCI films for corrosion resistance.

Various Forms of VCI Films Available

There are various ways in which VCI films can be best utilized depending on the situation and the need.

Read Also: Anti-Corrosion Paper

VCI Poly Film Bags, sheets, and Rolls

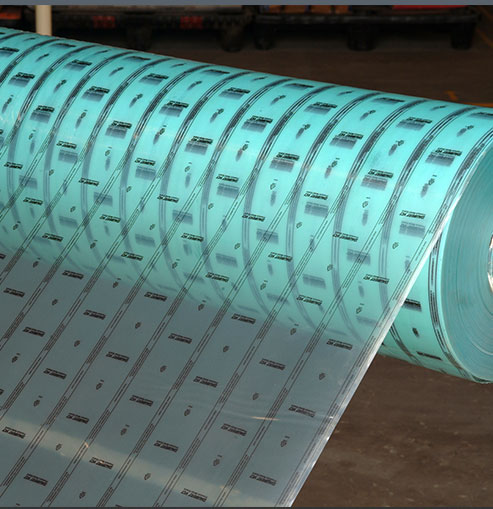

VCI films are available in transparent bags and rolls. Depending on the size of the material to be packed, the roll is uncoiled from the film roll and the object is sealed inside for the VCI chemicals and technology to begin the work. It works as a regular plastic bag but is infused with VCI. It is available as VCI film rolls for various sizes and weights of objects. VCI Film bags of customized size are also available.

Bubble Films and Foam

When extra cushioning is needed along with the VCI application in storage and transportation of items that are damage prone, then bubbles films, and foams are utilized.

Stretch wraps

These wraps work similarly to VCI poly film with the stretchable property added to it.

Conclusion

Zavenir Daubert being in this industry has earned themselves a name. With their VCI technology and corresponding products, it has been made possible to avoid corrosion during shipping and enable them to reach their destination in an intact state. This has ensured long-lasting objects and their quality are maintained for longer. Additionally, everything VCI based has been rushed into the market in the form of VCI film bags, and sheets to ensure protection from corrosion.

By Mudit Mathur

(Senior Manager, Product Management & Marketing)