September 2022

September 2022Rust Inhibition & Protection with VCI Foam

The entire world works on trading in the market. Where one industry specializes in its products and delivers the items to many countries to sell, it attains the packages for something else from another leader in the industry to make the sales in the present country. To ensure that what you send over as shipment and what is received is in the exact same condition to avoid conflicts, there is a need for precaution most specifically for the metal components. Therefore, there is a need for good rust inhibitors such as VCI Foam to ensure shipments of products guarantee customer satisfaction.

What is VCI Foam?

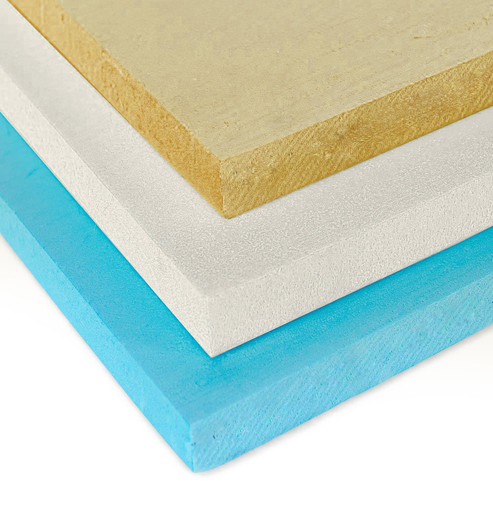

VCI Foams are non-abrasive and quite flexible to use when it comes to shipping materials and spare parts of a highly delicate nature. The foam provides cushioning to the items being transported in order to ensure physical protection against damage. This is best utilized when any industry wishes to send its products by packaging them tightly overseas. The foam is soft and plushy to absorb any jerks and mishandling by the unaware shipment crew.

While the foam itself is best for physical protection, it has VCI molecules embedded. These VCI molecules leave their host and form a protective layer over the metal surface of the item. This layer protects the metal item from corrosion. Therefore, when cushioning and corrosion prevention both are required, VCI foam is one of the best forms of rust inhibitors.

VCI foams are most commonly used for the transport of materials made of copper, zinc, steel, and iron alloys. One of the highlighting features is that VCI foam does not leave a residue when the product is opened at the destination. The look of the item is intact and the presence of VCI can only be experienced and not felt. These foams are custom-made as per the size requested by the clients. These are also available in long rolls to be used as needed.

Read Also: Anti-Corrosion VCI Films

Technology that supports VCI Foam for Rust Inhibition

VCI foams are most commonly based on Daubert VCI Technology by Zavenir Daubert. Zavenir Daubert is an old player in the rust inhibition and corrosion protection solutions industry. With its VCI Technology, it has brought forward VCI Foam best for the packaging of sensitive materials, electronics, subassemblies and spare parts, valuable equipment, and machinery spares.

According to the Daubert VCI Technology, the wrapping or protection material, VCI Foam, in this case, contains VCI molecules that can leave the host in close contact with the metal surface. The polarity of the molecules allows the VCI molecules to get attached to the metal surface and form a strong barrier of close-knit molecules. This layer is about 2-3 molecular levels with no space left so that it can protect the metal part from corrosion.

This technology has been utilized in the VCI Foam product in order to enable metal items to be protected from corrosion in transit when transported to other countries or cities.

Where VCI Foam can be utilized?

There are many application areas for VCI foam that includes:

- Electric panel and small components

- Telephone relays

- Circuit breakers

- Telecommunication equipment

- Firearms storage

- Marine navigation and communication equipment

- Utility boxes

- Metal parts and toolbox storage

- Operating and packaged electronic parts within compartments

- Fuse boxes and miscellaneous items

These are some of the common applications of VCI Foam. This product is considered the best and most effective in the shipping and storage industry arena for the purpose of protection from corrosion. It protects multi-metal products as well from rusting. It is very thin and lightweight and can be utilized easily in tight or restricted spaces. It is also environmentally safe and completely non-toxic.

Read Also: Anti-Corrosion Paper

Zavenir Daubert’s VCI Foam Packaging Solutions

VCI solutions by Zavenir Daubert have been trending in the industries for a long time now with the preferences increasing each day. This is the visible result of the efforts put in by the entire team of chemists and specialists to find the best technologies to combat the growing issues of corrosion. This has resulted in the development of several VCI based-products and solutions including:

- Daubert VCI Foams

- Daubert VCI Papers

- Daubert VCI Films

- Daubert NF VCI Emitter Cum Desiccant

- Daubert 5 VCI Emitters

Each of these solutions is a product based on Daubert VCI Technology, Daubert VCI Multilayer Technology, or Daubert VCI Desiccant Technology. The ultimate goal of every invention and development at Zavenir Daubert is to ensure that every industry relaxes in the face of impending corrosion and spoiling of its metal materials. It ensures the best packaging and shipping solutions with corrosion prevention.

By Mudit Mathur

(Senior Manager, Product Management & Marketing)