March 2023

March 2023Most Common Reasons Why Metal Parts Get Rust

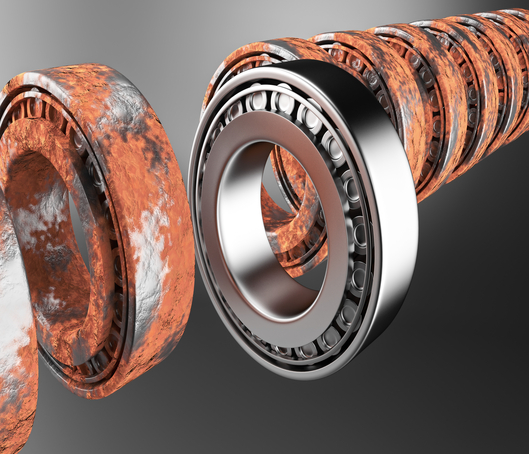

Rust is a common problem faced by metal parts and equipment, leading to reduced durability, strength and appearance. The formation of rust, also known as oxidation, is a natural process that occurs when metal reacts with moisture and oxygen in the air. This reaction results in the formation of iron oxide, which is commonly known as rust.

Most common reasons why metal parts get rust

1. Moisture and Humidity:

Moisture is one of the primary causes of rust, as it reacts with the metal to form iron oxide. High humidity levels and exposure to water can accelerate the rusting process, making it important to keep metal parts dry and protected from the elements.

2. Oxygen:

Oxygen is another key ingredient in the formation of rust. When iron reacts with oxygen, it creates iron oxide. This reaction can be accelerated by the presence of moisture.

3. Residues on the Metal Surface:

Residues from Manufacturing Processes, such as coolants, surface finishing chemicals, rinse waters, spirits and from airborne contaminants, such as pickling & plating lines or nearby polluting sources (factories, treatment plants, etc).

4. Salt or Salt Water :

Salt water is highly corrosive and can cause rust to form quickly on metal parts. This is especially true for parts that are frequently exposed to saltwater environments, such as those found in marine equipment and coastal areas.

5. Direct metal contact with Unprotected Hands:

Finger-prints deposit Salts on metal surfaces causing accelerated electro-chemical reaction. Critical in higher humid conditions even over short periods of time.

6. Poor Quality Metal:

Low-quality metal is often more susceptible to rust, as it may have impurities or other contaminants that can lead to corrosion. Additionally, metal parts that are not properly coated or treated with rust inhibitors are also more likely to rust.

7. Lack of Maintenance:

Regular maintenance is essential to preventing rust, as it helps to remove any build-up of rust and keep metal parts clean and protected. Failing to regularly maintain metal parts can result in rust forming, which can quickly spread and cause significant damage.

8. Exposure to Chemicals:

Certain chemicals can react with metal parts and cause rust to form. This is especially true for chemicals that are acidic or alkaline in nature, as they can break down the protective surface of the metal and allow rust to form.

9. Environmental Factors:

Environmental factors such as temperature fluctuations. Higher the Humidity and Temp fluctuation, more moisture condenses on metal. Export shipments are severely affected due to high Humidity and Temp fluctuations.

10. Storage, Packaging & Shipping conditions:

Storage: Location e.g., open, shed, closed shed, Packaging: Materials used e.g., wood, corrugation, packaging design, Shipment Conditions: Duration to Use, conditions during transit, etc.,

Read Also : How to Keep your Metal Parts Rust-free when Shipping Containers Overseas

In conclusion, rust is a common problem faced by metal parts and equipment, and there are several reasons why it can occur. By understanding the most common causes of rust, you can take steps to prevent it from forming and extend the life of your metal parts and equipment. This includes proper maintenance, using high-quality metal, avoiding exposure to corrosive elements, and using rust inhibitors. By taking these steps, you can ensure that your metal parts remain strong, durable, and rust-free for years to come.

How Daubert Rust Preventive Oil and VCI protects metal parts from rust?

Zavenir Daubert Rust Preventive Oil and VCI (Vapor Corrosion Inhibitor) are highly effective solutions for protecting metal parts from rust. The rust preventive oil forms a barrier over the metal surface, preventing moisture and oxygen from coming into contact with the metal and causing rust. The VCI, on the other hand, releases vapor that creates a protective layer around the metal, preventing rust from forming. Together, these products provide a comprehensive solution for protecting metal parts from rust. In addition, they are easy to use and can be applied to metal parts using a spray, dip, or brush. By using Zavenir Daubert Rust Preventive Oil and VCI, you can ensure that your metal parts remain rust-free and protected, even in harsh and corrosive environments.

Zavenir Daubert Nox-Rust® Rust Preventive Oils and its application.

Zavenir Daubert Nox-Rust® Rust Preventive Oils are specially formulated oils that protect metal surfaces from rust and corrosion. These oils are used in various industries such as automotive, aerospace and manufacturing to protect metal parts and equipment from rust and corrosion. The oils are applied to metal surfaces through dipping, brushing, or spraying, and they form a protective film that prevents moisture and other corrosive elements from coming into contact with the metal. The oils also contain rust inhibitors that slow down or stop the rusting process and extend the life of metal surfaces. Zavenir Daubert Nox-Rust® Rust Preventive Oils are an effective and cost-efficient way to protect metal surfaces and prolong their life.

Read Also : Different methods of Corrosion Prevention

Zavenir Daubert VCI® (Volatile Corrosion Inhibition) and its application.

Zavenir Daubert VCI® (Volatile Corrosion Inhibition) is a cutting-edge technology used in rust protection for metal parts and components. The VCI process works by emitting a vapor that covers the surface of the metal and creates a protective layer that prevents rust and corrosion from forming. The VCI molecules are specially designed to penetrate into tight spaces, crevices, and hard-to-reach areas, ensuring that every surface of the metal is protected. This innovative technology is ideal for use in a variety of industries, including automotive, aerospace, electronics, and manufacturing. The VCI process is easy to apply and is environmentally friendly, making it a popular choice for those looking for an effective rust protection solution. With Zavenir Daubert VCI® technology, metal parts and components can be stored for long periods of time without the risk of rust or corrosion.

By Mudit Mathur

(Senior Manager, Product Management & Marketing)