March 2023

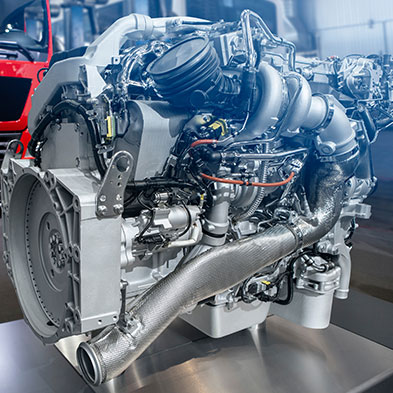

March 2023How to Ensure Rust Protection for Your Equipment and Machinery?

Rust is a common problem that affects machinery and equipment made of metal. Over time, exposure to moisture, salt, and other corrosive elements can cause rust to form on metal surfaces, leading to damage and potentially costly repairs. To prevent this, it's essential to take steps to ensure rust protection for your equipment and machinery. Here are some tips to help you get started:

Regular Cleaning: Regular cleaning of your equipment and machinery is crucial to keep them rust-free. Dirt and other contaminants can trap moisture, leading to rust and corrosion. Therefore, cleaning your equipment and machinery regularly can help prevent rust formation. Use a pressure washer or a cleaning agent to remove dirt and grime from your equipment and machinery. Once you are done with cleaning, make sure that the equipment is dry before putting it back into use.

Keep Equipment and Machinery Dry: Moisture is the primary cause of rust and corrosion. Therefore, it's crucial to keep your equipment and machinery dry. Store your equipment and machinery in a dry place, away from water sources. If your equipment and machinery get wet, dry them as soon as possible to prevent moisture from sitting on the metal surface.

Inspect Equipment and Machinery Regularly: Regular inspections of your equipment and machinery can help identify rust formation at an early stage. Early identification can prevent rust from spreading, minimizing the damage caused by corrosion. Inspect your equipment and machinery for signs of rust and corrosion, such as discoloration, flaking, and pitting. If you notice any signs of rust formation, take immediate action to prevent further corrosion.

Use Corrosion-Resistant Materials: Using rust-resistant materials for your equipment and machinery is another effective way to prevent rust formation. Materials such as stainless steel, aluminium, or coated metals are less prone to rusting and can withstand harsh environments.

Paint or Coat Your Equipment: Painting or coating your equipment and machinery can provide an extra layer of protection against rust. A good quality paint or coating can prevent moisture from reaching the metal surface, preventing rust and corrosion. Moreover, a well-painted or coated surface can also provide protection against other environmental factors such as UV rays and chemicals.

Apply Rust Inhibitor: A rust inhibitor is a protective coating that can be applied to metal surfaces to prevent rust formation. It works by creating a barrier that prevents moisture and other corrosive elements from coming into contact with the metal. There are many different types of rust inhibitors available, including paints, waxes, oils and coatings. They are easy to apply and can provide long-term rust protection. You can apply a rust inhibitor through a spray, brush, or dip method, depending on the product. Choose a product that is suitable for the specific type of metal you are protecting, and make sure to follow the manufacturer's instructions carefully.

Store Equipment Properly: Proper storage is critical to prevent rust formation. If you are storing equipment or machinery for an extended period, make sure it is in a dry, well-ventilated area. Avoid storing them in damp, humid areas, or outdoor locations where they are exposed to the elements. You may also want to consider using a dehumidifier to help remove any excess moisture from the air. Use covers or enclosures to protect your equipment from moisture and other environmental factors.

Use Desiccants: Desiccants are substances that absorb moisture from the surrounding air. They can be used to keep the air inside the storage area dry, preventing rust formation. Place desiccant packets in the storage area to keep the air dry.

Lubricate Moving Parts: Moving parts of equipment and machinery are vulnerable to rust and corrosion due to the constant exposure to moisture and air. Lubricating these parts can help prevent rust formation. Lubrication creates a barrier between the metal surface and moisture, preventing rust and corrosion. Regular lubrication of moving parts can keep them rust-free, extending their lifespan.

Schedule Regular Maintenance: Regular maintenance is essential for keeping your equipment in good working order and preventing rust formation. This may include lubricating moving parts, replacing worn or damaged parts, and tightening bolts and screws. Regular maintenance also provides an opportunity to inspect the equipment for signs of rust and corrosion.

Implement a Rust Prevention Plan: To ensure effective rust protection for your equipment, it's a good idea to develop a rust prevention plan. This may include a schedule for cleaning and inspections, as well as guidelines for choosing the right rust inhibitor and storing equipment properly. By having a plan in place, you can help ensure that your equipment stays in good condition for years to come.

Read Also : How To Package Metal Tools Properly So It Doesn’t Get Rust In Transit?

Long term Corrosion Prevention of Equipment and Machinery using Zavenir Daubert Nox-Rust® Wax and Coatings.

Zavenir Daubert Nox-Rust® wax is an excellent option for long-term corrosion prevention as it provides a protective barrier between the metal surface and the environment. The wax coating acts as a sealant that prevents water, air, and other corrosive agents from reaching the metal surface. Additionally, Nox-Rust® wax coatings are highly resistant to environmental factors like heat, cold, and UV radiation. This makes them an ideal solution for long-term protection against corrosion.

Nox-Rust® coatings are also an effective long-term solution for corrosion prevention. These coatings are specifically designed to provide exceptional protection against moisture, saltwater, and other corrosive agents. They can be applied to a wide range of surfaces, including metals, concrete, and plastics, providing a physical barrier that prevents corrosive agents from reaching the metal surface.

One of the significant benefits of using Nox-Rust® wax and coatings is that they are environmentally friendly. They contain no toxic or hazardous materials, making them an ideal solution for industries that prioritize sustainability.

In conclusion, Zavenir Daubert's Nox-Rust® wax and coatings are a highly effective and long-lasting corrosion prevention solution for equipment and machinery. They provide excellent protection against corrosion, even in harsh environments, and are environmentally friendly, making them an ideal choice for industries that prioritize sustainability.

By Mudit Mathur

(Senior Manager, Product Management & Marketing)