Applications of VCI Films in Industrial and Consumer Markets :

VCI (volatile corrosion inhibitor) films are widely used in both industrial and consumer markets for corrosion protection of various metallic components, equipment, and products. The following are some common applications of VCI films:

- Automotive : VCI films are used for the packaging and storage of automotive parts such as brake rotors, engine blocks, and other metallic components.

- Aerospace : VCI films are used for the packaging and storage of aircraft parts and equipment.

- Electronics : VCI films are used for the packaging and storage of electronic components such as circuit boards and microchips.

- Metalworking : VCI films are used for the packaging and storage of raw materials, finished parts, and tools in metalworking industries such as machining and stamping.

- Military : VCI films are used for the packaging and storage of military equipment and weapons.

- Consumer products : VCI films are used for the packaging and storage of consumer products such as bicycles, motorcycles, and power tools.

Understanding the Molecular Science Behind VCI Films :

VCI films are designed to protect metallic surfaces from corrosion by emitting volatile corrosion inhibitors that create a protective layer on the metal surface. The molecular science behind VCI films involves the use of chemicals that are capable of forming a monomolecular layer on the metal surface.

When VCI films are applied to the metal surface, the VCI chemicals evaporate and migrate to the surface of the metal, forming a thin layer of protective molecules. The protective layer of VCI molecules prevents the metal surface from coming into contact with moisture and other corrosive substances.

Types of VCI Films and Their Characteristics :

There are several types of VCI films available in the market, each with different characteristics and applications. The following are some common types of VCI films:

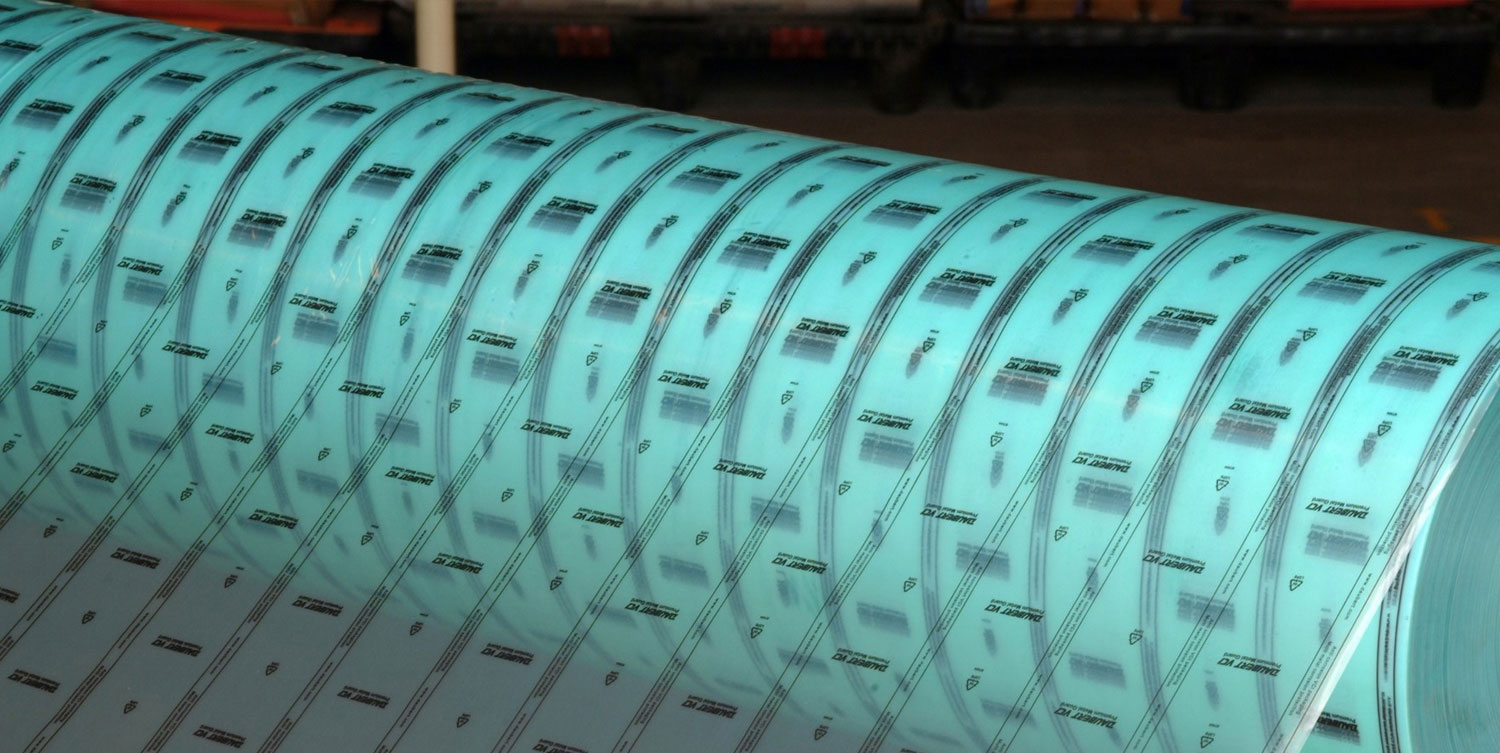

- Polyethylene VCI film : This type of VCI film is commonly used for packaging and storage of metallic components in industrial and consumer markets. It is flexible, durable, and provides excellent corrosion protection.

- VCI paper : VCI paper is a cost-effective alternative to VCI films. It is widely used for the packaging and storage of metallic components in industrial and consumer markets.

- Barrier VCI film : This type of VCI film is designed to provide superior barrier protection against moisture and other corrosive substances. It is commonly used in military and aerospace applications.

- Stretch VCI film : Stretch VCI film is designed to provide a tight and secure wrap around metallic components. It is commonly used in metalworking industries.

Advantages and Limitations of VCI Films for Corrosion Protection :

Advantages of VCI films for corrosion protection include:

Easy to apply : VCI films are easy to apply and do not require any special equipment or training.

Cost-effective : VCI films are cost-effective compared to other corrosion protection methods.

Non-toxic : VCI films are non-toxic and safe for use with food products.

No residue : VCI films do not leave any residue on the metal surface.

Limitations of VCI films for corrosion protection include :

Limited lifespan : VCI films have a limited lifespan and may need to be replaced periodically.

Inconsistent protection : The effectiveness of VCI films can be affected by factors such as temperature, humidity, and the size of the enclosed space.

Limited protection against external damage : VCI films only provide protection against corrosion and do not protect against external damage such as scratches and dents.

Guidelines for Handling, Storing, and Disposing of VCI Films :

The following guidelines should be followed when handling, storing, and disposing of VCI films:

- Store VCI films in a cool, dry, and well-ventilated area.

- Do not expose VCI films to direct sunlight or high temperatures.

- Avoid storing VCI films near sources of ignition or combustible materials.

- Handle VCI films with clean hands or gloves to avoid contamination.

- When disposing of VCI films, follow local regulations for plastic waste disposal. Some VCI films may be recyclable, while others may need to be disposed of in a landfill.

- Before reusing VCI films, check for any signs of damage or deterioration that may affect their effectiveness.

By following these guidelines, VCI films can be used safely and effectively for corrosion protection in a wide range of industrial and consumer applications.