July 2023

July 2023Enhancing Metalworking Efficiency with the Right Metal Cutting Fluid

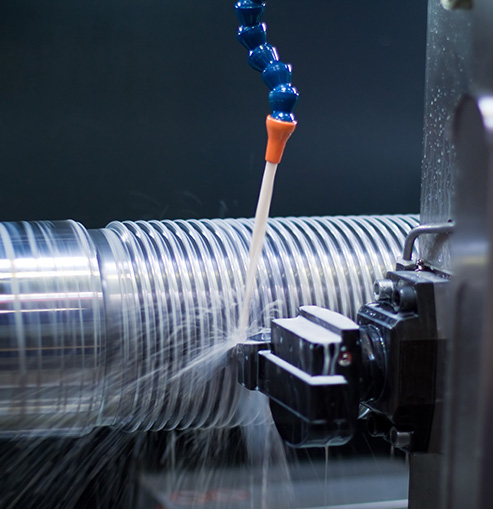

Enhancing metalworking efficiency relies on the use of the appropriate metal cutting fluid. Metal cutting fluids, such as cutting oils or coolants, play a crucial role in lubricating, cooling, and removing chips during machining operations. By reducing friction and heat, they extend tool life, improve surface finish, minimize workpiece deformation, and increase cutting speeds. Proper selection of the cutting fluid based on factors like machining operation, workpiece material, and environmental considerations ensures optimal performance. By using the right metal cutting fluid, metalworkers can enhance efficiency, productivity, and overall machining performance in various industries.

What is Metalworking? Why Metal Cutting or Machining Operations Required

Metalworking refers to the process of shaping and manipulating metal materials to create various products or components. It encompasses a wide range of operations, including cutting, drilling, milling, turning, and more.

Metal cutting or machining operations are required to shape metal into desired forms, remove excess material, and achieve precise dimensions. These operations are essential in industries such as automotive, aerospace, construction, and manufacturing. Metal cutting or machining operations allow for the creation of intricate designs, precise parts, and components that meet specific requirements, enabling the production of various metal-based products that serve critical functions in numerous applications.

Metal Cutting Fluids: Importance, Types and Application

Metal cutting fluids, also known as metalworking fluids or cutting oils or coolants, are liquids used in metalworking processes to improve efficiency and performance. They provide lubrication, cooling, and chip removal during cutting operations.

Metal cutting fluids are important as they enhance tool life, surface finish, and prevent tool wear. They come in various types, including straight oils, soluble oils, semi-synthetic fluids, and synthetic fluids. The selection of the appropriate cutting fluid depends on factors such as the machining operation, workpiece material, cutting speed, and environmental considerations. Metal cutting fluids find application in industries such as automotive, aerospace, machining, and fabrication.

Selection of Right Metal Cutting Fluid for Specific Machining Operation

The selection of the right metal cutting fluid for a specific machining operation is a critical factor that can significantly impact the efficiency and performance of the process. Several considerations should be taken into account when choosing the appropriate cutting fluid :

1. Material being machined : Different cutting fluids are designed to work with specific materials. For example, ferrous metals may require cutting fluids with EP (extreme pressure) additives, while non-ferrous materials may benefit from straight oils or water-based fluids. Understanding the compatibility between the cutting fluid and the workpiece material is crucial.

2. Machining operation : The type of machining operation being performed is another important factor. For instance, turning, milling, drilling, and grinding operations may have different requirements in terms of lubrication, cooling, and chip evacuation. Some cutting fluids are better suited for heavy-duty operations, while others are more suitable for high-speed or precision machining.

3. Cutting speed : The cutting speed or feed rate also influences the selection of the cutting fluid. High-speed machining may require a cutting fluid with better cooling properties to control the heat generated during the process. Conversely, slower machining speeds may allow for different types of fluids that provide better lubrication.

4. Surface finish requirements : If achieving a specific surface finish is crucial, the cutting fluid's impact on the workpiece's surface quality should be considered. Some fluids can improve the surface finish, while others may leave residue or require additional cleaning processes.

5. Tool life requirements : Extending tool life is a common objective in metalworking operations. Certain cutting fluids, such as those with additives or specific formulations, can help reduce tool wear and extend tool life. Considering the expected tool life requirements and the compatibility between the fluid and the tooling is important.

6. Environmental considerations : Environmental regulations and sustainability goals may influence the choice of cutting fluid. Water-based fluids or biodegradable options might be preferred to minimize environmental impact.

7. Cost-effectiveness : Evaluating the cost-effectiveness of the cutting fluid is essential. Factors like fluid consumption rate, ease of maintenance, and overall performance should be considered to determine the long-term economic benefits.

To select the right cutting fluid, it is recommended to consult with Zavenir Daubert, consider performance data, and conduct trial runs. Testing the fluid's performance in specific machining operations and evaluating its impact on tool life, surface finish, and overall efficiency can help identify the optimal cutting fluid for the specific application. Regular monitoring and maintenance of the cutting fluid, such as filtration and concentration control, should also be conducted to ensure consistent performance over time.

Benefits of Using Metal Cutting Fluids in Metalworking Operations

Using metal cutting fluids in metalworking operations provides several benefits.

1. Extended tool life : Metal cutting fluids provide lubrication, reducing friction and wear on cutting tools. This extends the tool life, reducing the need for frequent tool replacements and increasing cost-effectiveness.

2. Improved surface finish : Cutting fluids help dissipate heat generated during cutting, preventing workpiece overheating and improving surface finish. This results in smoother, more precise surfaces and reduces the need for additional finishing operations.

3. Chip removal : Metal cutting fluids aid in chip evacuation by lubricating and cooling the cutting zone. This prevents chips from clogging the cutting tool or interfering with the machining process, leading to improved productivity and reduced downtime.

4. Cooling and heat dissipation : Cutting fluids act as coolants, dissipating heat generated during cutting operations. By maintaining lower temperatures, they help prevent workpiece distortion and improve dimensional accuracy.

5. Enhanced productivity : The combination of lubrication, cooling, and chip removal provided by cutting fluids allows for increased cutting speeds and feeds. This leads to improved productivity and shorter machining cycle times.

6. Environmental and health benefits : Some cutting fluids are formulated to be environmentally friendly and have low health risks for operators. Using these fluids helps comply with environmental regulations and promotes a safer working environment.

Metal cutting fluids contribute to improved tool life, surface finish, chip removal, cooling, productivity, and environmental safety in metalworking operations. Their application results in cost savings, higher quality products, and increased operational efficiency.

Zavenir Daubert has products such as X-HONE®, X-CUT® and X-COOL® as Metal Cutting Fluids to solve a myriad of metalworking problems efficiently.

By Mudit Mathur

(Senior Manager, Product Management & Marketing)